Technology • 25.03.2021

Refrigeration and the cold chain: optimising and anticipating with remote monitoring of facilities

Cold is essential to our lives and part of our daily routine. Without even realising it, we rely on the cold throughout the day: for food, of course, but also for our comfort, our leisure activities, our health…

While its role is vital and is being highlighted during this vaccination period, managing it properly remains a challenge. For example, today, 2/3 of the food produced in the world is thrown away. In terms of emissions, if food waste were a country, it would be the 3rd largest producer of greenhouse gases…

How can cold management be improved?

Difficulty of implementation, complex regulations, containment of facilities, direct and indirect emissions, continuity of processes, food safety, etc. Managing refrigeration installations can be complicated.

To simplify the daily lives of refrigeration professionals and users, Matelex offers a global remote supervision solution for installations. With its permanently accessible web platform and range of alerts, this solution improves the performance of installations and reduces their environmental impact, while making it easier to monitor them.

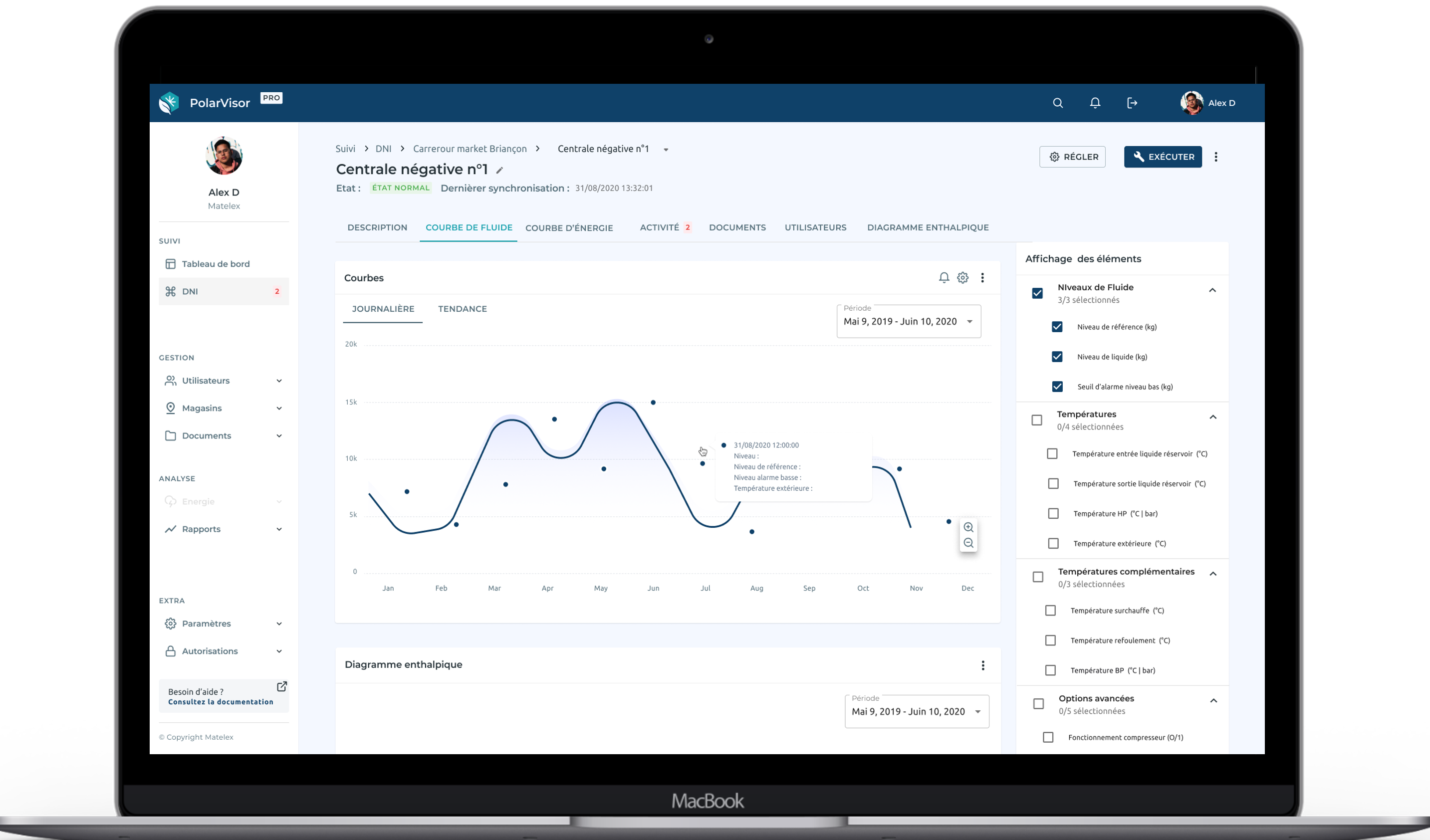

A web platform dedicated to remote surveillance

The Sentinelle web platform, dedicated to facility monitoring, is continuously fed with data from the Intelligent Level Detector (ILD) and its energy management modules. This data, captured every 4 to 5 seconds, is analysed and displayed by Sentinelle in the form of simple indicators, advice and customisable alerts.

This comprehensive and constantly updated overview means that we can react as quickly as possible to any anomalies, drastically reducing the risk of a break in the cold chain and loss of goods due to malfunctioning installations.

- Responsiveness: rapid response thanks to real-time data and alerts (leaks, energy, technical)

- Simplicity: a single platform for centralised monitoring of installations

- Savings: save time, optimise servicing and prevent breakdowns

There are major environmental benefits: the reduction of direct emissions linked to refrigerant leaks and of indirect emissions through the optimisation of refrigerant charging and the monitoring of energy drifts means that the overall environmental impact of the installations can be significantly reduced.

Tested on a panel of large-scale food retail facilities, the solution resulted in savings of 79% in refrigerant quantities compared with the traditional method. This method involves visiting the installation at periods defined by the regulations (based on the tonnes of CO2 equivalent contained in the installation). Unfortunately, it is not always possible to detect leaks within a reasonable timeframe. All it takes is for a leak to be triggered the day after a visit for it to continue until the next leak test, leading to major losses in the facilities that can jeopardise their operation.

Support for the use of connected refrigeration solutions

To support operators and users in the use of connected solutions for refrigeration, Matelex provides simplified regulatory information and offers support sessions for the installation and use of its solution.

To find out more about how connected solutions can improve the performance of refrigeration installations, contact us!